Head on a Platter

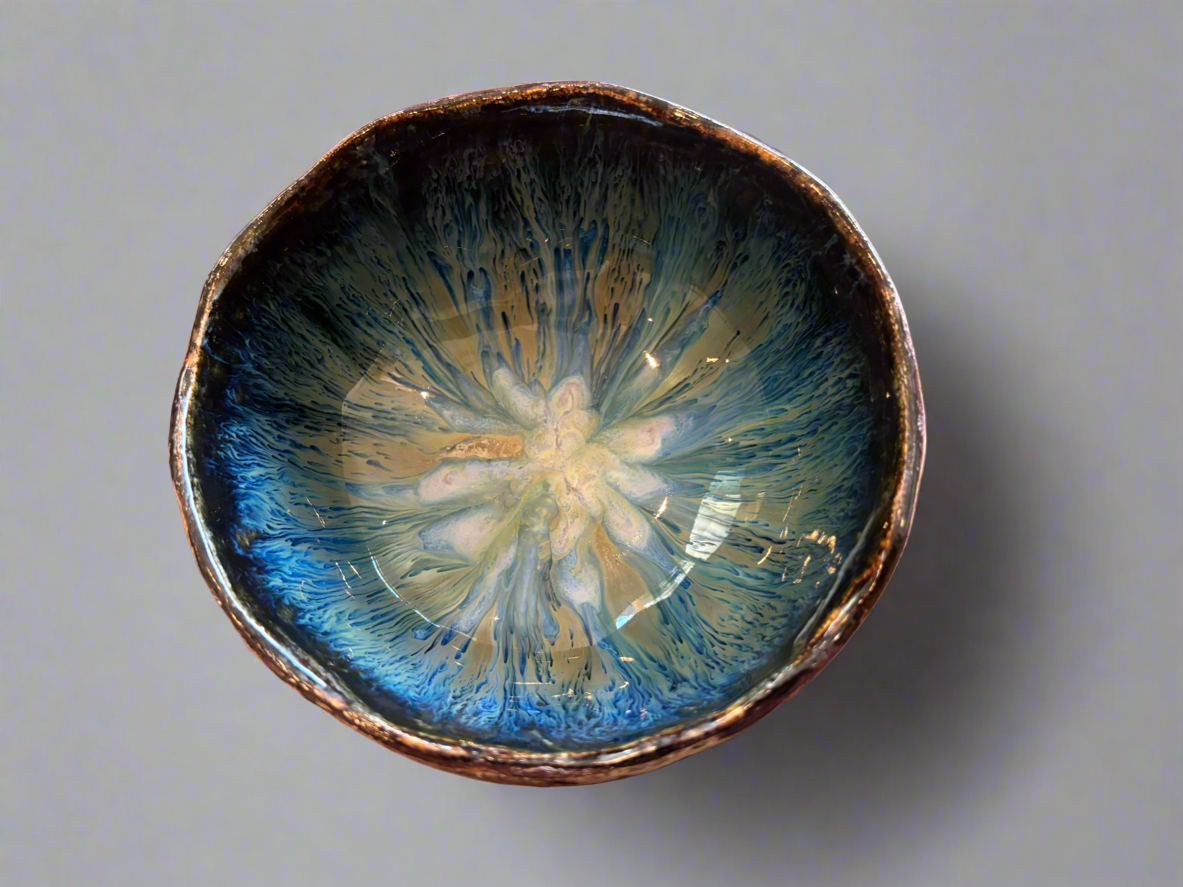

Custom sets - layered reactive glaze bowls

Custom sets - layered reactive glaze bowls

Couldn't load pickup availability

Please get us touch for commissioning your own custom set.

Whether to use as an individual bowl or when building up your set - these bowls are hugely popular, both because of their look and their versatility!

Handbuilt in stoneware clay and glazed with layered reactive glazes, the result is a rather spectacular piece that will make you smile every time you use it!

By layering reactive glazes, the inside of this bowl comes alive - one shade when it's time for cocktails and nibbles in the garden, another when you are having that lovely candlelit dinner inside. Never boring, never the same.

Iron oxide wash highlights the natural textures on the outside of the bowl. This ensures that the raw clay contrasts beautifully with the glossy interior.

Should you require any more items / when out of stock, please do get in touch to discuss ordering more or for special commissions.

Details:

Approx size* (diameter x height): 14cm x 6cm

Microwave and dishwasher safe

* Due to the handmade nature of each item, measurements can vary up to 1cm

---

A brief description of the building process of these tableware bowls:

1. Preparing clay

After wedging a ball of clay - similar to kneading dough - the clay is rolled out into an even slab before being cut in the size and shape I need.

2. Forming the bowl

Depending on the size of the bowl, I then either drape over or press into plaster moulds that I made earlier. When making a set, for example, the tiny pots used for salt / sauces / pickles etc are literally just formed with my fingers and left to firm up. However, for these soup / stew sizes, I used the plaster moulds to support the clay while it firmed up enough to continue air drying on its own.

For the biggest bowls, the process is usually a combination - using plaster supports for an hour or two, and then continue adding hand rolled coils of clay until the size and shape I want.

3. Decorating the wet clay bowl

Once the clay is firm enough to support its own shape, I press natural textured pieces into the clay. Leaving the outside unglazed, this raw, texturised clay will contrast beautifully with the highly glossy interior. The texture can be created with seeds, bark, stones, shells - or, for a commission, any item that has special meaning to yourself / the recipient.

4. Wait (the hardest part!)

Depending on the weather, it can take anything between 2 - 4 weeks on the shelf for these bowls to dry to "bone dry" stage. It is essential that they dry slowly and evenly as that will prevent cracking during the drying process.

5. Bisque firing

Firing in the kiln to 1000°C to remove any remaining moisture and strengthen the clay

6. Glazing and final firing

Here comes the magic part: I layer different colours of reactive glazes, using techniques such brushing / dripping / drizzling / "blobbing" to get the patterns I want. Whilst I can influence it, you never know exactly how it comes out, which is brilliant and makes every single one unique! It usually has 6 - 9 layers of glaze before it goes in the kiln.

The second firing takes the bowl to maturity - these are fired slowly to 1220°C. This ensures that stoneware items are safe to use in the microwave and dishwasher.

7. Enjoy!

Share